Selling since 1984

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Laddomat with electronic pump for central heating boilers

A necessary thermoregulation equipment for the central heating system. Maximising the benefits of hot water absorption in the water storage tank (heat buffer or heat cache) and protects the boiler return water temperature flow.

These solutions are particularly well known in the gasification of fuels (eg. in wood gasification combustion). The following functions are performed by Laddomat to secure return water of the boiler, optimum use of the time efficiency of the boiler, hot water receiving, water thermal layers in heat buffer without stirring, minimising the destructive process of low-temperature corrosion (by water condensation) and in most cases an occasion to extended warranty for the boiler (For boilers operating in an installation with Laddomat, eg. in some ATMOS gasification boilers).

Also noteworthy is the fact that the water thermal layers of the buffer cache when charging or collection (accumulation) of heat are not unnecessarily stirred, in this way the heat buffer refills with heat in the upper layer much faster.

Laddomat heat controller and minimum return water temperature protection unit comes in several versions, which can be divided due the boiler nominal output power:

- Laddomat 11-200 with pump Wilo Yonos Para HF10 - for central heating boilers with a nominal output of up to 160 kW

- Laddomat 11-200 with pump Wilo Yonos Para HF12 - for central heating boilers with a nominal output of 185 kW

An additional division of Laddomat return water protection comes due to the fact of different thermostatic valve opening temperatures (this parameter is boiler dependent and corresponds to the return water temperature of a certain boiler):

- thermostat insert with an opening temperature of 72 °C - version for 11-200

ATTENTION! For lack of a combination of the desired product configuration thermostat insert option (opening temperature), select the appropriate Laddomat unit for your central heating boiler and buy an additional thermostat insert (and replace it - See the PDF manual of how to replace the thermostat insert of a Laddomat unit).

The main functions of a Laddomat with circulation pump:

- The boiler can quickly reach the operating temperature (boiler and flue reduced tar conditions)

- During the heating (initial phase of combustion), the cold water is heated at the bottom of the tank to protect the tank against corrosion due to the low-temperature corrosion process (condensation)

- Providing a high and constant water temperature in the buffer cache and low flow for optimal thermal water layering (divided into cold and hot water, if the buffer is not yet fully charged)

- After completion of the combustion process, the rest of the boiler heat (ex. from the heat exchanger) is brought into the buffer tank (central heating economy)

- at circulation pump stop or power failure, heat flow from the boiler to the buffer tank takes place with natural circulation of the water heating system, because the Laddomat has an integrated circulation system

How does a Laddomat work in the central heating system

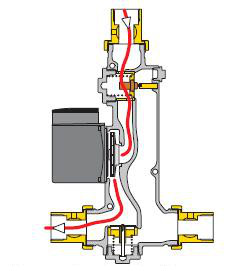

Starting the boiler

To achieve a high level of efficiency and low emissions of unburned substances, it is important that the boiler reaches the working temperature quickly. This is achieved by the circulation pump that is starting as soon as combustion (firing) begins. This prevents cold water from the bottom of the accumulator tank (thermal store) cooling the boiler unnecessarily, through self-circulation. The circulation pump can operate in three different ways. Firing has started and the pump has started as well. The thermostat cartidge has not started to open yet. The valve plate of the self-circulating thermostatic valve is kept closed by the water pressure from the circulation pump.

Boiler operating phase

The boiler has reached operating temperature. The thermostat cartridge has opened and mixes the cold water from the accumulator accumulator tank. The mixed water entering the bottom of the boiler has a temperature of about 5–20°C below the opening temperature of the thermostat cartridge. The higher the output of the boiler and the higher the temperature of the water exiting the boiler, the more cold water is mixed in from the bottom of the accumulation tank. This is the same characteristic that allows Laddomat to separate effectively the thermal water layers, while charging the accumulator tank under all different operating conditions in different boilers.

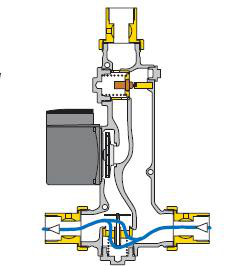

Final phase

During the final phase of charging the by-pass port in Laddomat is completely closed to the top of the boiler. All water is routed to the accumulation tank which becomes fully charged.

Self circulation when the boiler has stopped

If a flue thermostat or similar equipment is installed, it will stop the pump immediately after the fire goes out. The advantage of stopping the pump quickly after the fire goes out is that the cool return water from the radiator circuit flows into the bottom of the boiler through self-circulation. The stored heat in the boiler is then transferred to the top of the accumulator tank, and the house then benefits from it. Stopping the pump when heating ceases, either manually or automatically, is important for one further reason. The hot water in the accumulation tank will otherwise be mixed with cold radiator water down to the closing temperature of the thermostat cartridge. If the tank is heated to 90°C and the thermostat cartridge closes at 75° the whole accumulator tank falls to this temperature if the pump is not switched off.

Self circulation in event of a power cut

If a power cut occurs during firing, self-circulation starts automatically through the easily opened valve check, on the condition that the water in the accumulator tank is colder than the water in the boiler. The self-circulation power is created by the weight difference between lighter hot water and heavier cold water. If the accumulator tank is completely heated all the way to the bottom, self-circulation will be limited, and the boiler could still hit boiling point. This boiling can be stopped by feeding a small quantity of cold water directly into the bottom of the boiler through the system filling tap. In the event of a sustained power cut, the whole house can be heated through self-circulation, if the pipe-runs and dimensions are suitable. The firing should be matched to the output which can be transferred to the storage accumulator tank through self-circulation.

Data sheet

| Weight [ kg ] | 10.0 |

| Thread type | External thread (GZ) |

| Outlet and inlet supply size [ inch ] | 5⁄4'' |

| Installation | Horizantal, Vertical, Wall, Internal |

| Max. working temperature [ °C ] | 100 |

| Min. working temperature [ °C ] | 5 |

| Opening temperature [ °C ] | 72 |

ℹ️ Viewed reviews are moderated. We do not verify that they come from customers who have purchased the product.