Selling since 1984

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Boiler for pellets PEREKO QmPell Evo 8 kW

Ecological Heating:

QmPell Evo Boiler has been designed with economical heating in mind, suitable for every family. It is perfectly suited for use in single-family homes and utility rooms. The boiler is designed to meet the latest emission standards and streamline the fuel delivery process. QmPell is made of 6mm thick boiler steel and features an intelligent control system.

High Work Efficiency:

The QmPell Evo series represents an innovative achievement in terms of performance, automation of operation, and environmental care. Thanks to the compact construction of the boiler, it can be adapted to any boiler room. The new design of the heat exchanger significantly reduces heat losses and minimizes the need for cleaning.

Controller in QmPell Evo Series:

- Allows for managing the operation of the installation: pumps, pellet feeder, and fan

- Ensures optimal pellet combustion and reduces its consumption by even several dozen percent.

- Provides user safety through applied systems

- Ensures compatibility with optional modules: controller and room thermostat

- Optionally allows for monitoring the operation and changing boiler operation parameters via the Internet

Advantages:

- In the 8 kW model, integrated fuel tank - Other models in this series have an external fuel loading hopper.

- Intuitive controller - horizontal shelves of the heat exchanger allow for easy cleaning of the boiler interior.

- Intuitive controller operation - with operation of 3 pumps and the possibility of managing boiler operation online

- Horizontal arrangement of heat exchanger shelves - facilitates cleaning

- Burner - made of high-quality steel and easy to clean

- Exhaust fan - ensures more precise pellet combustion

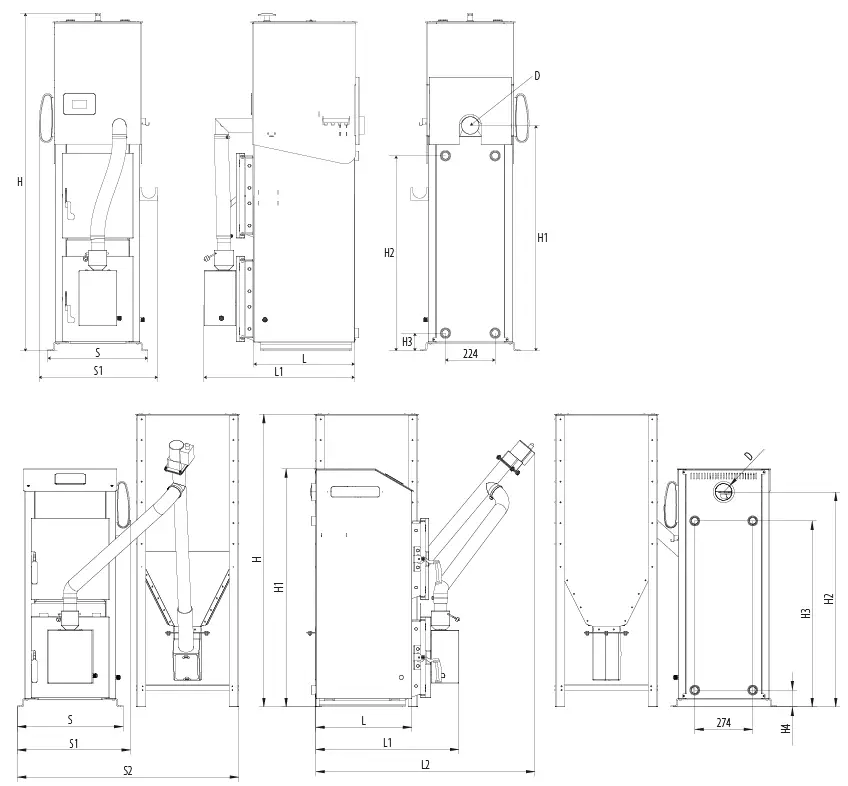

| Parameter | Unit | Model | |||

|---|---|---|---|---|---|

| 8 | 12 | 18 | |||

| Dimensions | D | [mm] | 80 | ||

| L1 | 676 | 677 | |||

| L2 | — | 1036 | |||

| L | 454 | ||||

| H | 1522 | 1385 | |||

| H1 | 1016 | 1126 | 1366 | ||

| H2 | 880 | 1016 | 1262 | ||

| H3 | 80 | 880 | 1125 | ||

| H4 | — | 80 | |||

| S | 450 | 500 | |||

| S1 | 539 | 535 | |||

| S2 | — | 1047 | |||

| Primary Fuel | — | WOOD PELLET | |||

| Nominal Heat Output | [kW] | 8 | 12 | 18 | |

| Heat Output Range* | 8.3 – 1.9 | 12.2 – 3.2 | 18.1 – 4.6 | ||

| Volume of Heated Rooms** | [m3] | 325 | 400 | 600 | |

| Surface Area of Heated Rooms** | [m2] | 130 | 160 | 240 | |

| Fuel Loading Capacity | [L] | 60 | 180 | ||

| Boiler Water Capacity | [L] | 35 | 38 | 51 | |

| Maximum Operating Pressure | [bar] | 2 | |||

| Minimum Required Flue Gas Draft Pressure*** | [mBar] | 0.2 | |||

| Flue Gas Temp. | Nominal Power | [°C] | 116.01 | 113.59 | 122.1 |

| Minimum Power | 74.54 | 74.86 | 61.7 | ||

| Flue Gas Mass Flow | Unit | Model | |||

| 8 | 12 | 18 | |||

| Flue Gas Mass Flow | Nominal Power | [g/s] | 9.3 | 10.7 | 13.5 |

| Minimum Power | 2.6 | 4 | 6.6 | ||

| Fuel Consumption at Nominal Power with 17 MJ/kg Calorific Value | [kg/h] | 1.89 | 2.79 | 3.82 | |

| Water Flow Resistance at Nominal Power | ΔT=10K | [mbar] | 4.76 | 5.6 | 12.12 |

| ΔT=20K | 1.89 | 1.93 | 6.93 | ||

| Supply Water Temperature | [°C] | min. 57 / max. 85 | |||

| Minimum Boiler Return Temperature | 50 | ||||

| Continuous Operation | [h] | 20 | 42 | 30 | |

| Boiler Electrical Supply 230 V – 50 Hz / 400 V – 50 Hz | [W] | 230 V, 50 Hz, 6 A | |||

| Electrical Power | 285 | ||||

| Standby Power | 3 | ||||

| Power Consumption at 30% Load | 12 | 15 | |||

| Power Consumption at 100% Load | 17 | 23 | 28 | ||

| Auxiliary Power Demand at Max Power | 17 | 23 | 28 | ||

| Auxiliary Power Demand at Min Power | 12 | 15 | 15.04 | ||

| Noise | [dB] | < 65 | |||

| Boiler Mass (without water) | [kg] | 180 | 241 | 281 | |

| Supply and Return Pipe Diameter | — | GW 1” | |||

| Thermal Efficiency According to PN-EN 303-5:2012 (nominal power – minimum power) | [%] | 89.89 – 89.29 | 91.27 – 90.96 | 88.26 – 87.73 | |

| Energy Class | [%] | A+ | |||

| Controller / Fan | — | YES / YES | |||

| Boiler Operation in Excess Pressure [+] / Negative Pressure [–] of Flue Gas at Outlet | — | [–] | |||

| Warranty | — | 60 months for heat exchanger tightness, 24 months for components | |||

| Heat Exchanger Material | — | P265GH Steel PN-EN 10028 | |||

| Temperature Setting Range on Controller | [°C] | 50 – 85 | |||

ℹ️ Viewed reviews are moderated. We do not verify that they come from customers who have purchased the product.